- 10-inch touchscreen

- since 1985 -

Professional Bubble Film Machine Manufacturer

- since 1985 -

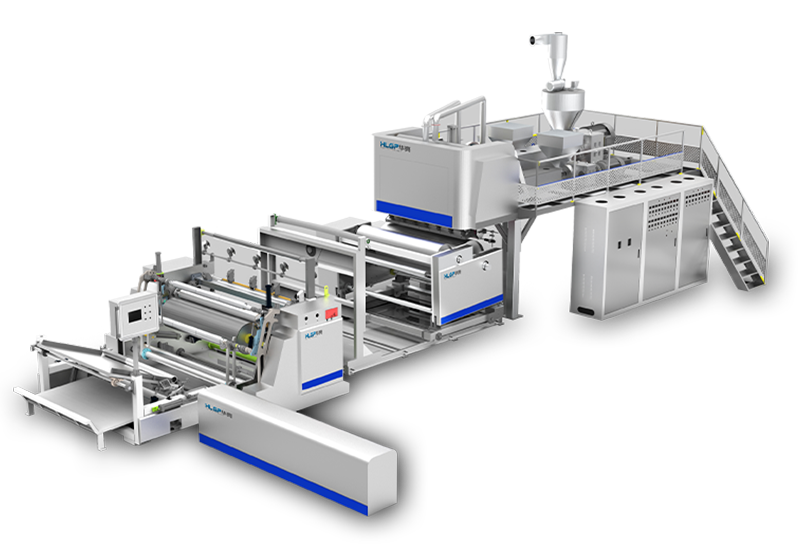

The L/D ratio is 34:1, the screw has been nitrided to make it more stable and durable, and the T-shaped die is made of 2311 die steel to ensure a more uniform film and longer life.

Stretch Film Extrusion Machine with a speed design of up to 250 meters per minute, this machine enables rapid processing and production of stretch film, contributing to increased efficiency and output.

The working speed ranges between 150 and 200 meters per minute, ensuring consistent and reliable performance during operation, leading to stable and high-quality output.

| No. | Item | Specs |

| 1 | Model: | HLCPE-2000-120-80-80 |

| 2 | Industrial Power Supply: | 3 phases industrial power supply |

| 3 | Total Power: | 350 KW |

| 4 | Main Raw Material: | LLDPE, & MLLDPE |

| 5 | Thickness of Film: | 10~50 microns (minimum thickness can be 8 microns) |

| 6 | Width of the Useful Film: | Maximum width: 2000 mm |

| 7 | Film Layer Structure: | ABC Three layers or ACBCA Five layers |

| 8 | Designed Linear Speed: | 250 M/Min |

| 9 | Extrusion Output: | 400-600 kgs/h |

| 10 | Dimensions (L×W×H): | 14*6.5*5 M (for reference only) |

| 11 | Gross Weight: | 22T (for reference only) |