- since 1985 -

- since 1985 -

Are you in the packaging industry and searching for a high-efficiency 3-layer air bubble film making machine? Whether you need protective packaging for fragile goods, electronics, or shipping materials, a reliable bubble film production line is essential.

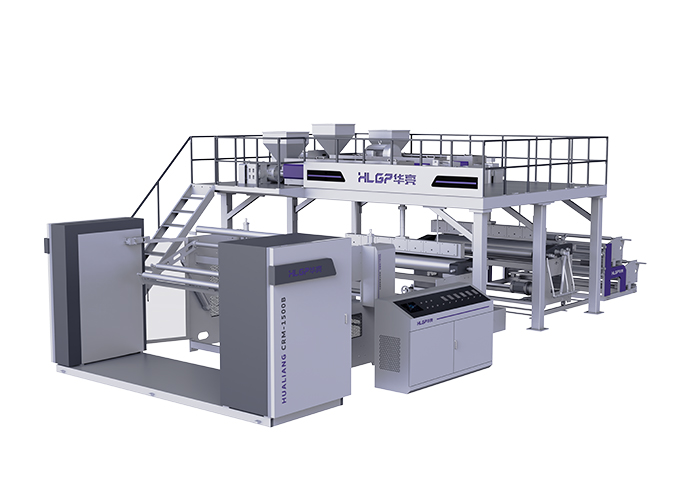

HLGP, a trusted manufacturer in the field, offers an advanced 3-layer bubble film extruder with impressive output, speed, and automation features.

But what makes this machine stand out? Let’s explore its key features, production capabilities, and why it’s an excellent investment for packaging manufacturers.

Bubble film, also known as air cushion film, is widely used for protective packaging due to its lightweight, shock-absorbing properties. A 3-layer bubble film machine enhances durability and strength compared to single or double-layer films, making it ideal for heavy-duty applications.

HLGP’s machine is designed for high-speed production, energy efficiency, and automation, ensuring maximum output with minimal manual intervention.

1. High Output & Speed for Maximum Productivity

Output: 170-250 kg/h (adjustable based on material and thickness)

Max Speed: 35 meters per minute – one of the fastest in the industry

Screw Design: L/D ratio of 34:1, ensuring efficient melting and uniform extrusion

2. Multi-Layer Extrusion for Stronger Bubble Film

The machine uses three extruders to produce a high-quality 3-layer film structure, which can include:

LDPE (Low-Density Polyethylene) – for flexibility

LLDPE (Linear Low-Density Polyethylene) – for puncture resistance

HDPE (High-Density Polyethylene) or PP (Polypropylene) – for added strength

Recycled materials – for cost-effective, eco-friendly production

3. Advanced Cooling & Bubble Formation

Water-cooling system ensures rapid and uniform cooling for consistent bubble size.

Bubble roller stabilizes the film formation, reducing defects.

4. Fully Automated Operation for Efficiency

Automatic cutting & winding – reduces labor costs and increases efficiency.

PLC control system – monitors temperature, speed, and tension for precision.

Meter counting & alarming – tracks production length and alerts operators when adjustments are needed.

5. Adjustable Film Width for Versatility

Film width ranges from 1600mm to 2500mm, catering to different packaging needs.

This 3-layer bubble film extruder is perfect for:

✔ Packaging manufacturers producing protective films for e-commerce, electronics, and fragile goods.

✔ Recycling companies looking to incorporate recycled materials into bubble film production.

✔ Industrial suppliers needing high-volume, automated packaging solutions.

✅ Higher Production Speed – 35 m/min means faster turnaround times.

✅ Lower Energy Consumption – Efficient screw design reduces power usage.

✅ Minimal Waste – Precise cutting and automated controls optimize material usage.

✅ Durable Construction – Built for long-term industrial use.

If you need a high-speed, automated, and reliable 3-layer air bubble film making machine, HLGP’s model is an excellent choice. With its high output, adjustable width, and energy-efficient design, it’s ideal for businesses looking to scale their packaging production.

Interested in learning more? Contact HLGP today to discuss your bubble film production needs!