- Hydraulic changer:

- since 1985 -

- since 1985 -

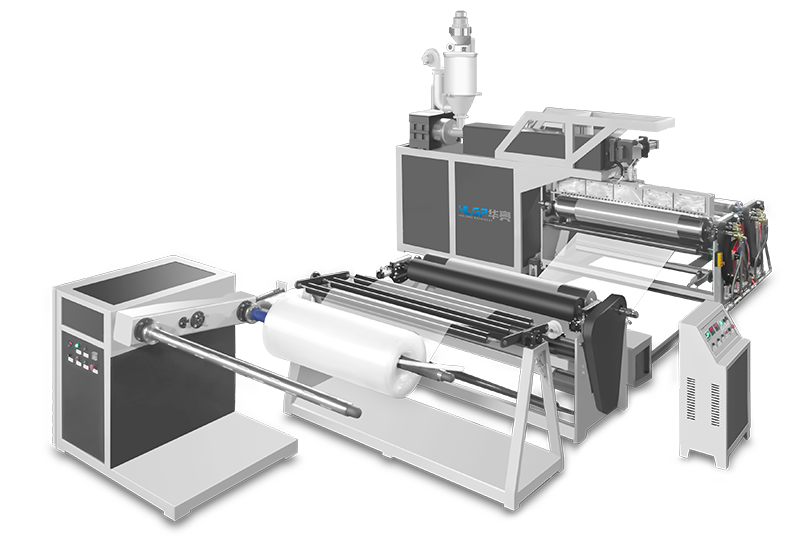

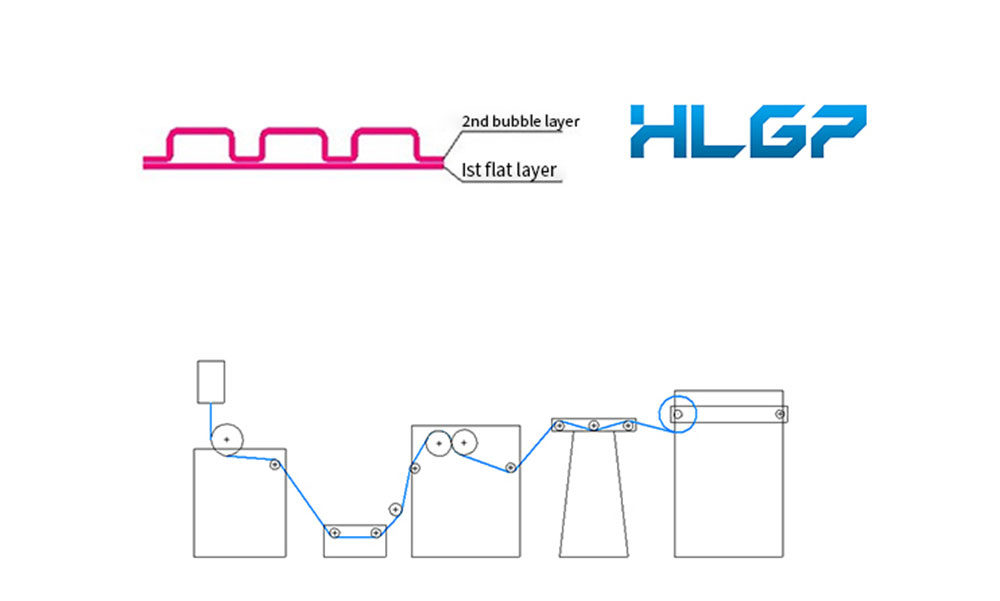

This bubble film machine uses a variety of materials such as LDPE, LLDPE, HDPE, PP, etc., and can produce 2 layers of bubble film. Its T-shaped mold is made of 45# steel, P20h or 2311#, and can form bubbles through bubble rollers and water cooling to achieve faster and higher-quality film production.

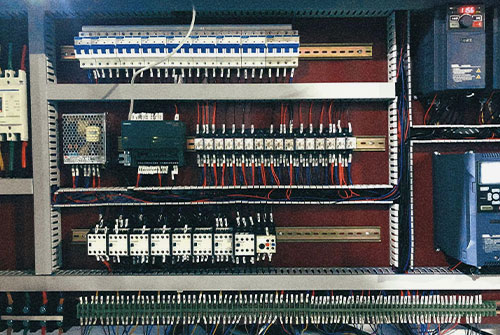

The equipment is equipped with a PLC system that allows precise control and monitoring of the machine and temperature. In addition, the bubble film machine also has automatic winding and meter counting alarm functions, which has high work efficiency and can meet the automation needs in production.

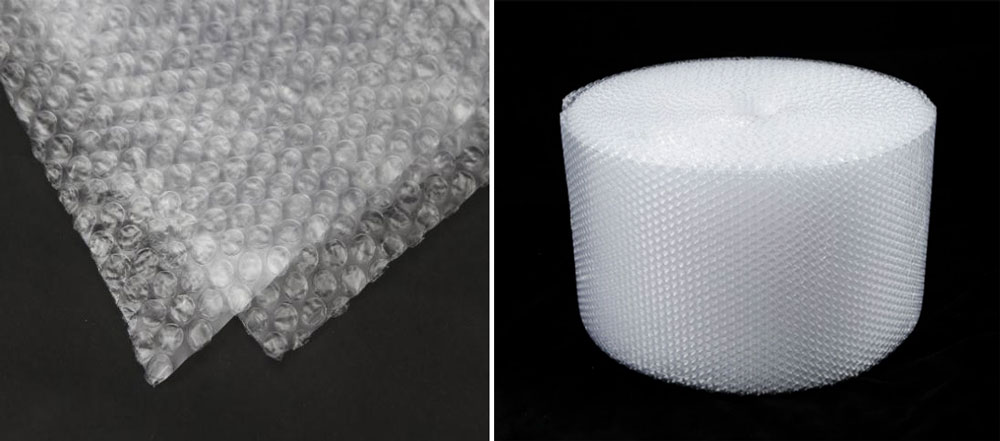

Bubble wrap is a light and transparent plastic packaging material that is safe and odorless. Its excellent cushioning, shock-absorbing and scratch-resistant properties make it an ideal protective cushioning material.

Due to these excellent qualities, bubble film is widely used in packaging of daily necessities, electronic products, precision instruments, ceramics, glass products and other industries.

|

Model |

HLPE-1600 |

HLPE-2000 |

HLPE-2500 |

|

Screw dia |

80 |

90 |

100 |

|

L/D |

34:1 |

34:1 |

34:1 |

|

Motor |

30kw |

45kw |

55kw |

|

Final product |

1600 |

2000 |

2500 |

|

Output |

100KG |

120 |

160 |

|

Total power/Heating power |

85/47kw |

110/60kw |

140/75kw |

|

Line speed |

35m |

35m |

35m |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

380/3/4/50 |

380/3/4/50 |

|

L*W*H |

9300x2900x2500 |

9600x3300x2500 |

10000x3800x2500 |

|

Material |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

|

Max Speed |

35M/min |

||

|

Output |

Customized by configuration |

||