- since 1985 -

- since 1985 -

The versatility of bubble wrap gives it a wide range of applications, from wrapping to protecting various types of items.

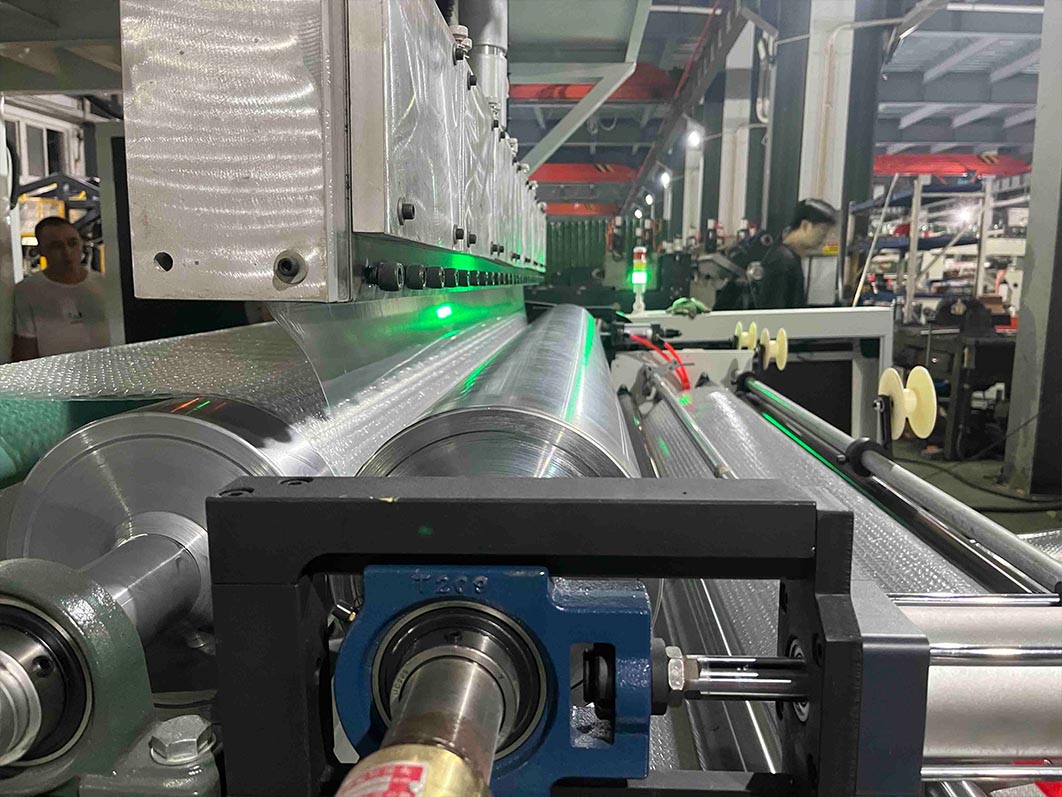

Bubble film machines play a vital role in the production of bubble wrap, as they are able to efficiently extrude, bubble form, cool, cut and rewind plastic film to form the final bubble wrap product.

Manufacturers can adjust raw material ratios, extruder parameters and cooling processes to achieve the desired properties of bubble packaging, such as bubble size, thickness and strength.

Bubble wrap is made of plastic and its production process involves the following key steps:

1. Raw material preparation

The main raw material for making bubble film is polyethylene (PE) resin particles. These resin pellets are stored in hoppers and prepared for use in the manufacturing process.

2. Extrusion

The core step of bubble film production is extrusion. In the extruder, PE resin pellets are heated and melted, forming a viscous plastic melt. This melt is forced through a die with specific openings in the extruder, forming a continuous plastic film.

3. Bubble formation

Air is introduced into the film coming out of the extruder through a pair of rollers, creating bubbles inside the film. Often, one roller is slower than the other, causing bubbles to form and stretch.

4. Cooling and solidification

The formed bubble film is cooled and solidified by a series of cooling rollers and fans. This helps maintain the shape and stability of the bubble wrap.

5. Cutting and rewinding

After the bubble film is cooled and solidified, use a cutting machine to cut it to the required width. It is then wound onto a winding machine to form a roll of bubble-wrapped product.

6. Printing and customization

If desired, printing or customization of labels, graphics, or text can be added to the bubble wrap. This step is usually done early in the manufacturing process.

7. Packaging

Finished bubble wrap rolls are typically cut to the required length and packaged for shipping and sale.

A large amount of discarded bubble packaging materials poses a potential threat to the environment, and it is crucial to strengthen its recycling and reuse.

Bubble film recycling is the process of collecting, processing and utilizing waste bubble film materials to reduce environmental pollution and save resources.

By recycling and reusing bubble wrap materials, the need for new plastic is reduced, thereby reducing greenhouse gas emissions from landfills and waste incineration facilities.

This helps address the challenges of climate change and mitigate the greenhouse effect.

Unrecycled waste bubble wrap material often ends up in landfill or is incinerated as waste, producing greenhouse gases such as methane in comparable amounts to plastic waste.

Bubble wrap recycling is an important sustainable practice that helps reduce plastic pollution, lower resource consumption and improve environmental quality.

While there are still challenges to overcome, through innovation, education and collaboration, together we can advance bubble wrap recycling and make a valuable contribution to the future of sustainable packaging.

This effort not only benefits the environment, but also creates economic opportunities and promotes social sustainability.